In the aeronautic industry, where mass is a significant design factor, cockpit and passenger seats are subject to rigorous static and dynamic regulatory criteria as well as live comfort assessments. Working with limited physical prototype designs limits the chances of creating new, cutting-edge seats and results in traditional, overweight designs. And when you try optimizing the weight vs. cost ratio to meet interior noise targets, you can run into delays and cost overruns in the design cycle. Ultimately, the penalty for late interventions caused by poor designs is, unfortunately, an increase in both weight and cost.

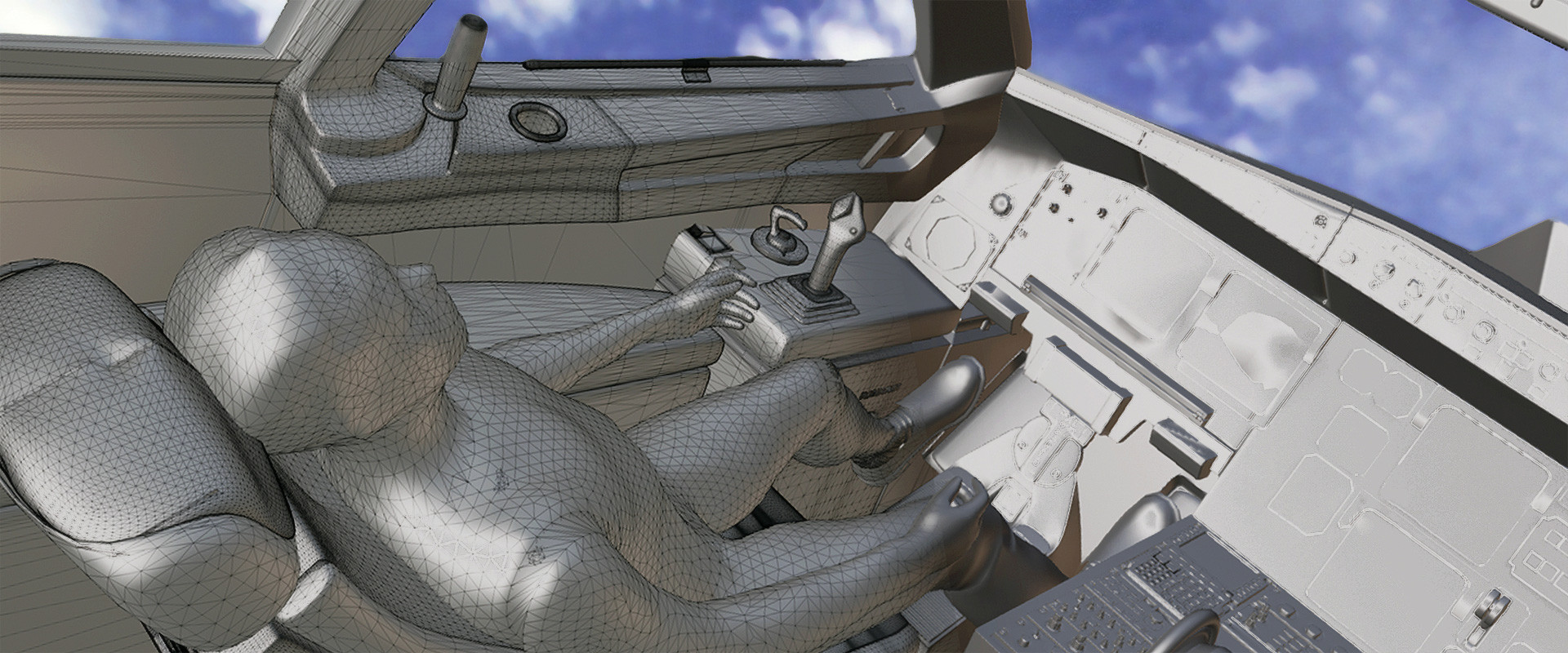

Engineers need virtual prototyping to design and engineer cabin and cockpit interiors for quick iterations on variants that facilitate decision-making early in the design process and innovation with confidence.

ESI Seat, Acoustics & Interior solutions accurately evaluate all criteria, simultaneously, and can deliver precise individual and overall results. For a fraction of the time and cost compared to physical prototyping, you can:

run numerous trials for various configurations early in the design phase

optimization and fine-tune performance simultaneously to maximizing comfort, safety, and weight reduction

virtually pre-certify before ever building a single physical validation prototype

Benefits of OurInterior Solutionfor Aircraft

Design and engineer cabin and related components to meet demanding and evolving performance objectives at lower cost

Engineer new cockpit layout to minimize the risk

Explore differing design variants and strategies early in the design cycle without impacting time to market

Anticipate product performance issues to make trades-offs that meet optimal lightweight design results

Innovation performed in confidence, reducing risk, meeting design objectives whilst reducing design cost, time and prototype stages

Highly accurate modeling provide reliable results without then need for physical cross-checking and allows virtual pre-certification

Virtually assess tests for new cabin and the cockpit passenger experience: seating comfort depending on passenger anthropometry and posture, sound insulation designed to meet noise targets, individualized thermal comfort or sound experience