Successfully managing global energy supply is crucial to all infrastructures and the maintenance of society worldwide. Energy production and distribution involve many industries whose main challenges today revolve around productivity, continuity, safety, and reliability.

Our customers in the Energy and Power sector face a number of continuously evolving challenges that range from addressing safety, environmental and sustainability issues to managing financial risks and tighter technical requirements. Companies have to comply with increasingly complex regulatory requirements and improving operational performance. Addressing these issues relies on ad-hoc engineering modeling methodologies that must accurately tackle operational and accidental events applicable to the production and transportation installations. Therefore, effective realistic modeling is paramount to staying competitive. Effective realistic modeling calls for a high level of innovation.

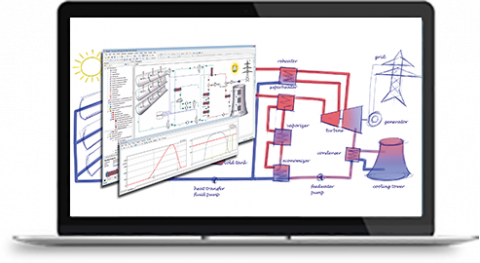

虚拟原型解决方案for the Energy Industry

那些创造和供应能源的人面临着一个复杂的难题:追求创新和风险破坏,或者紧贴运行顺利但不符合当今期望的过程?该冒险将数字化变成可靠的价值和投资回报率?人们对这些挑战有充分的意识,ESI的承诺是帮助能源技术的制造商和运营商,从传统资源到可再生能源,实施正确的数字工具,使他们能够充满信心地创新和有效地运营。

能源场中的制造商,分销商和供应商使用ESI解决方案进行设备的“建造”和“操作”建模,以评估性能,维护计划的优化以及拆除过时的设备。从石油和天然气到核天然气和风车,在能源领域拥有30多年的经验,ESI的广泛软件套件解决了各种学科,以满足这个多方面行业的严格需求。

Explore我们的解决方案

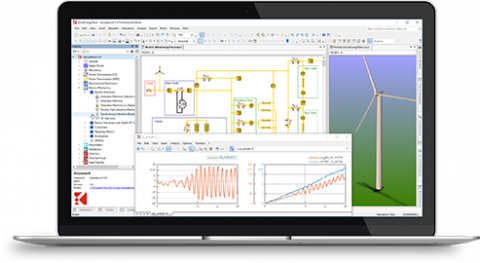

Reaching the optimal health monitoring for wind turbines and reducing operation and maintenance costs while ensuring a high level of performance remains the biggest challenge for Wind Farms. Today, new approaches allow you to alleviate remaining gaps (e.g. data availability, representatively, and physical behavior) and address the specificities of each farm.

In this webinar, we highlight how the coupling of physics-based model with data analytics and machine learning enriches turbine monitoring and opens new fields for Wind Farm owners in their predictive maintenance strategy.

“In the global context of energy transition towards a low carbon society, each stakeholder faces the challenges of innovation,performance and safetycompliance with standards to deliver the best time to market.”

联系我们

虚拟原型制作for Energy Technologies受到信任

全世界,供应商,制造商和工程合作伙伴都使用ESI解决方案来设计和优化能源系统,例如ABB Automation, Aker Solutions, Caterpillar Energy Solutions, Eaton betway手机官网Industries, EDF, E.ON Energy Research Center (RWTH Aachen), Framatome, Fuji Electric, GE Jenbacher, Mitsubishi Electric, Mitsubishi Hitachi Power Systems, NEC, Robert Bosch, Siemens, SKF,Vaillant,Veolia或Voith Hydro ...